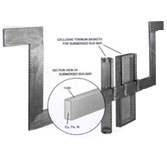

Submerged bus bar and baskets.

Submerged bus bar and baskets. |

Previously, bus bars were by definition made out of copper and were installed above the tanks. Annoyances such as corrosion of copper, difficulty and danger of adding anode metals, heat generation due to electrical contact resistance in electrolysis, and plating defects caused by corroded and fallen copper compound were accepted as inevitable events. Now by incorporating our SUN Z-R technology, bus bars can be submerged and we are able to avoid all of these annoyances. Submerged bus bars have now become the leading choice for many industries including print circuit makers and steel manufacturers.

|

|

|

Key Advantages

- Low voltage operation and energy saving are realized by cutting loss of electric power, cutting heat generation by contact resistance between bus bar and hooks, and realizing 100% electro efficiency since bus bar is submersible. Since the bus bar is clad, and not loose lined, it is an integral item and independent tests have shown that there is no difference in resistance between solid copper bar and our SUN Z-R submerged bus bar. Loose lined bar on the other hand has a resistance that is more then 5 times higher then our SUN Z-R submerged bus bar.

- Easy and secure adding of anode metals into the baskets. Because there are no obstructions above the baskets, it becomes a much easier task.

- Zero fall-off of deposited impurities and copper corroded compounds into the bath. Because a highly corrosion resistant lining is applied to the copper bar, you no longer have to worry about problems such as plugging through holes on print circuit boards or roughness of coating. Our submerged bus bars consist of a copper core (or steel) that is clad with a thin layer of a highly corrosion resistant metal such titanium using our SUN Z-R process.

- Corrosion is non-existent. Relatively maintenance free. No more labor costs necessary for polishing or replacing copper bus bars when you use our submerged bus bars.

- Reduced ventilation fans. With our submerged bus bars the size of ventilation fans can be reduced because obstructions above the tank such as bus bar have been removed.

- Available in any shape (flat, round, square) and any custom length or configuration.

|

| Titanium clad copper submerged bus bar. |

|

|

Partial platinum cladding on contact surface of titanium clad bus bar. |

Submerged bus bars are perfectly suited for electro-plating, electro-purification, caustic soda electrolysis, and aluminum anodizing. Submerged bus bars can be made with a core made out of copper or steel and can be clad with titanium, niobium, zirconium, tantalum and others as well. Submerged bus bars are available in any size and any quantity and as all products manufactured by SPF Corporation of America, these are custom designed and engineered to fit customer requirements best.

|

Conductivity test results

| Sun-Z-R (Titanium Clad Bar) |

Loose Lined Titanium Bar |

Solid Copper Bar |

| 23µ Ohms/35cm |

128µ Ohms/35cm |

23µ Ohms/35cm |

| 0.66µ Ohms/cm |

3.66µ Ohms/cm |

0.66µ Ohms/cm |

|

Field results of submerged bus bar replacement

| Solution |

Product |

Anode |

Amps |

Voltage Before |

Voltage After |

Energy Reduction |

| Hard Chrome |

Piston Rods |

Pt&Pb |

4200 |

10-11 |

7.8-8.5 |

22.70% |

| Hard Chrome |

Machine Parts |

Pb |

7000 |

7.00 |

5.5 |

21.40% |

| Nickel Strike |

Electrical Parts |

Ti Basket (Soluble Ni) |

700 |

4.00 |

3.5 |

12.50% |

| Cu Sulfate |

PCB |

Ti Basket (Soluble Cu) |

80 |

1.80 |

0.80 |

55.50% |

| Cu Sulfate |

PCB |

Ti Basket (Soluble Cu) |

800 |

8.50 |

7.00 |

17.60% |

| Cu Sulfate |

PCB |

Ti Basket (Soluble Cu) |

340 |

3.00 |

2.10 |

30.00% |

| Cu Sulfate |

PCB |

Ti Basket (Soluble Cu) |

340 |

3.20 |

2.50 |

21.90% |

|

|

|

SPF Corporation of America:

|

Telephone |

(713) 856-8855 |

Fax |

(713) 856-8834 |

Postal Address |

6529 Cunningham Rd.

Ste 2105

Houston, TX 77041, U.S.A. |

eMail |

|

Web Address |

|

|

| |

|

SPF Europe BV:

|

Telephone |

31 455 23-1474 |

Fax |

31 455 23-0470 |

Postal Address |

De Koumen 30, 6433 KD Hoensbroek, The Netherlands |

eMail |

|

Web Address |

|

|

| |

|

SPF Company LTD.:

|

Telephone |

81 52 871-4121 |

Fax |

81 52 872-1397 |

Postal Address |

5-1, Horita Doori, Mizuho-Ku, Nagoya, 467-0862, Japan |

eMail |

|

Web Address |

|

|

|

| |

|

|